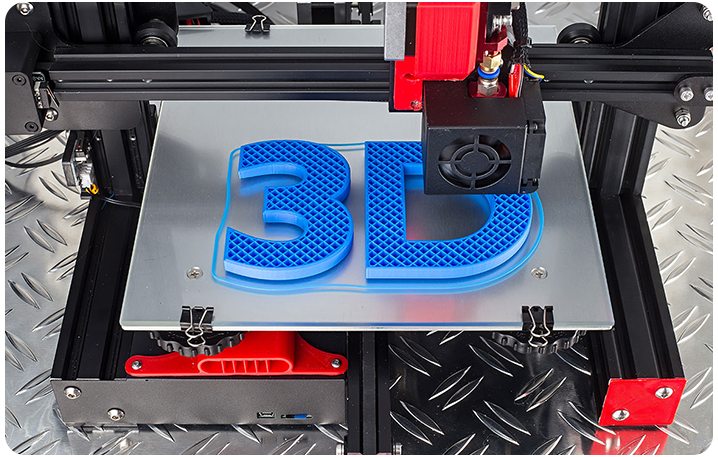

Use 3D printing to realize you idea!

3D printing is great for prototyping. By using physical prototypes you can minimize the time and cost of the product development. You need to have a lot of capital to make expensive molds for pouring plastic - instead use 3D printing to test and refine your product until it is ready for production in bulk, thus saving money and time!

An individual solution often requires some specific part that is impossible to find or too expensive to purchase! 3D printing is a good solution - we will print the necessary part without the minimum order quantity according to your given specification. It is also possible to rebuild some parts by using the old ones!

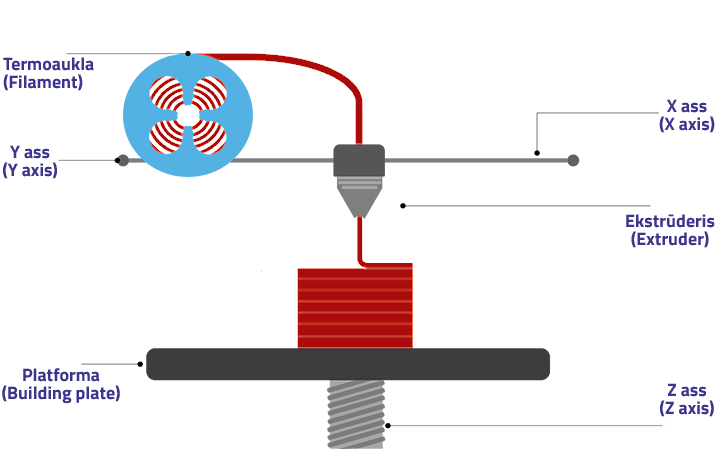

We offer FDM (Fused Deposition Modeling) printing technology. This process uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work.

ABS (Acrylonitrile Butadiene Styrene) ABS plastic is an impact-resistant thermoplastic and amorphous polymer (which means it does not show the characteristics of crystalline solids). It is opaque in nature. ABS is made up of three monomers called Acrylonitrile, Butadiene, Styrene. ABS material, thanks to its supreme properties, are utilized in many products. The most commonly seen products are keyboard keys used in computers and laptops, toys, lego blocks, face guards, various components in automobiles, etc.

PLA (Polylactic Acid) is one of the most popular thermoplastics derived from lactic monomers extracted from natural sources like sugarcane or corn. It is a versatile biodegradable plastic with good applicability to several products. Polylactide is the second most widely used bioplastic (the most used bioplastic is thermoplastic starch) worldwide. The PLA characteristic is similar to Polypropylene(PP) and Polyethylene(PE). It is relatively inexpensive to produce as it can be done in the existing manufacturing machine, originally designed for traditional thermoplastics derived from petroleum.

Given all the above information, it can be concluded that the two materials have many similarities. Both are thermoplastics and can achieve good results when 3D printed. Both materials can be post-processed - sanded, glued, painted, etc. However, there are also nuances that must be taken into account depending on the requirements and application of the product.

1) 3D modelis. Lai izprintētu detaļu ir nepieciešams 3D fails. Populārākie failu formāti ir .STL, .STEP, .GCODE.. Ja 3D modelis Jums nav pieejams, pastāv iespēja to izstrādāt izmantojot rasējumus, attēlus, fizisku detaļu vai idejas aprakstu. Ja neesat pārliecināts par savu failu vai Jums ir nepieciešams to sagatavot - droši sazinieties un mēs vienosimies par risinājumu!

2) Detaļas pielietojums. Jau sākumā ir svarīgi saprast, kāds būs detaļas pielietojums un kādām slodzēm tā tiks pakļauta. Tas ļaus izdarīt pareizo materiāla izvēli kā arī noteikt printēšanas uzstādījumus. Jo precīzāka un izturīgāka detaļa ir nepieciešama, jo vairāk laika būs nepieciešams tās izprintēšanai!

3) Izmaksas. Programmatūra aprēķina, cik ilgs laiks būs nepieciešams detaļas izprintēšanai ar noteiktiem uzstādījumiem. Izmaksas tiek noteiktas atkarībā no printēšanas ilguma. Standarta cena 8.00 EUR / Stundā. Tomēr, katrs projekts ir individuāls un esam atvērti dažādiem sadarbības veidiem, droši sazinieties, lai vienotos par turpmāko sadarbību!